Common Applications for Steel Tubing

Steel is an incredibly versatile metal. There are over 100 grades of steel. Depending on the alloy type, some are brittle while others are extremely flexible. Certain types of steel are incredibly corrosion-resistant, while others provide a perfect solution for sterile environments.

Thank you for reading this post, don't forget to subscribe!This metal is used to fabricate everything from surgical scalpels to construction materials. Today, let’s focus on one specific product type: steel tubing. Read on to learn about some of the many applications for tubular steel.

Industrial Uses

There are few industries that don’t make at least some use of steel tubing. It can be found in just about every industrial machine, hydraulic equipment, conveyor belts, mills, and other parts of any modern industrial plant. Original equipment manufacturers can visit webcotube.com to find the specialized products they need for machine manufacturing and repairs, including multiple alloys and grades designed to meet the unique requirements of a wide variety of industries.

Oil and Gas Extraction and Transportation

Steel tubing can also be found in just about every oil or gas extraction operation. Oil and gas industry operators typically choose corrosion-resistant alloys that are best able to withstand harsh weather and constant exposure to moisture. Coiled tubing products can be found in many upstream oil and gas applications and some geothermal applications.

Aerospace and Military Applications

Steel’s high resistance to pressure and extreme conditions make it the perfect material for manufacturing aerospace and military components used for fluid transports. The military often uses steel tubing in its vehicles and as weapons components, while the aerospace industry relies on tubular steel for constructing everything from landing gear to exhaust stacks. Welded and seamless stainless and carbon steel pressure tubing can be found in everything from airborne personnel carriers to rockets.

The most common stainless-steel alloys used in aircraft and aerospace applications are chromium and nickel alloys, which offer superior heat and corrosion resistance. In aerospace applications, steel tubes are often manufactured to a much wider diameter. It can be either welded or seamless.

Transportation and Freight Shipping

Just about every vehicle on the planet features stainless steel tubing in its engine and fuel lines. This versatile, durable material is perfect for transporting everything from gas and oil to steam and smoke without risking damage to other sensitive components. Don’t just think mufflers. Tubular steel can also be found in modern vehicles’ suspension systems, control systems, and fuel injection lines.

Construction and Engineering

It should come as no surprise that steel makes the perfect material for large-scale construction and engineering applications. In these industries, steel tubes may be referred to as circular hollow structural sections (HSS). Some manufacturers also make square and rectangular HHS. In their circular form, HSS are often used as columns, building components, and as scaffolding. Tubular steel has a high weight-bearing capacity, so engineers and architects prefer it for applications that are not subjected to multiple loads.

Plumbing Tubes

Technically, steel tubes are not the same thing as steel pipes. Pipes are measured by outside diameter and wall thickness, while tubes are designated a nominal pipe size. Pipes also tend to be smaller. While pipes are typically found inside homes and commercial buildings as part of their interior plumbing systems, tubing is used for things like underground water service, potable water distribution, and radiant heating.

Medical Applications

Steel tubing plays a vital role in the medical industry. It’s used in both hospital equipment and patient assistance and conveyance applications. Surgical tools may feature medical steel tubing, as do some specialized implants, and even the ubiquitous stethoscope. In the average hospital, tubular steel can be seen in wheelchairs, IV stands, patients’ beds, and many other areas. Medical-grade stainless steel offers excellent resistance to moisture, chemicals, and pathogens, making it a practical and hygienic choice for these unique applications.

HVAC Applications

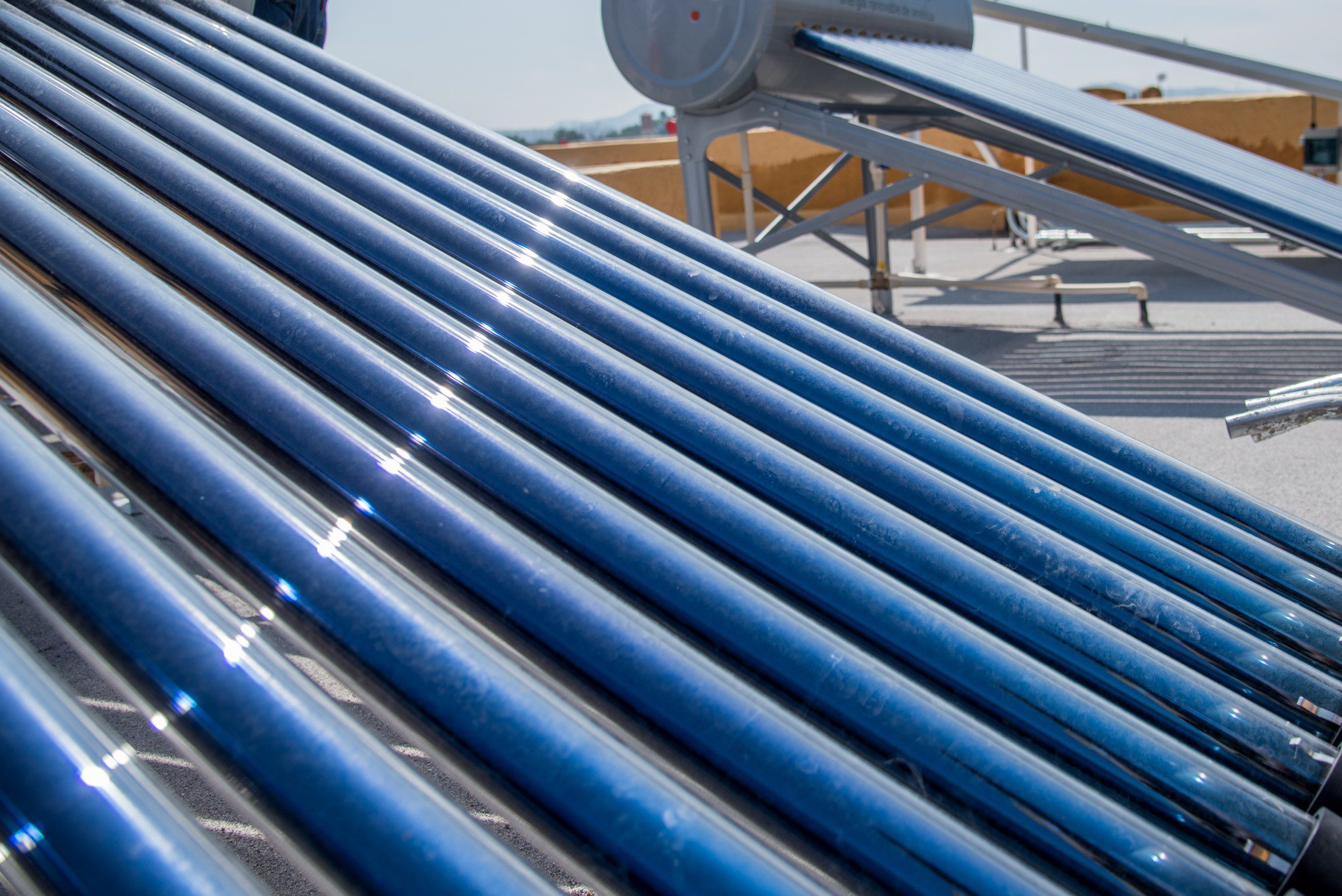

HVAC systems make extensive use of steel tubing. It can be found in heat exchangers, heaters, air conditioners, and even certain parts of ductwork in both residential and commercial buildings. HVAC manufacturers choose grades of steel that are able to withstand heat to ensure that their equipment will not break down under the stresses of normal use.

Agricultural Uses

Steel tubing can even be found on most modern farms and orchards. It plays a vital role in powering hydraulic harvesting and processing equipment and may be used to transport everything from water to herbicides and pesticides. Some grades of steel are highly resistant to corrosion from both water and chemicals.

Architectural Applications

Not all the uses for steel tubes are structural. Architects and even artists sometimes incorporate tubular steel into their designs. Fully tubular structures have become very popular in China in recent years, where architects appreciate not just their structural performance but also their increased aesthetic appeal.

How to Choose the Right Type of Tubular Steel

The best way to figure out what grade of steel or alloy to use is to contact a specialized tubing manufacturer for advice. Do some brainstorming before calling a representative. In order to give the best recommendations, they’ll need to know:

- The specific application for the product

- Whether it will be used in a maritime environment

- How much pressure the tubular steel will need to withstand

- Whether it will come into contact with chemicals or other corrosives

- What diameter and wall thickness will be required?

- Whether the tubing will be exposed to extreme heat

- If the tubing will be straight or will need to be bent

- What budgetary concerns may come into play

The best approach is to give a company representative as much information as possible and keep an open mind about options. There are many types of steel and steel alloys, and tubing comes in a wide variety of shapes and sizes. A specialist can help clients make the right choice, even if that means manufacturing custom tubing.

The Bottom Line

The invention and popularization of tubular steel have revolutionized many industries. When buying steel tubes, it’s important to make an informed decision since every type of tubing is approved for different applications. Choose a reputable manufacturer that specializes in producing steel tubes and get in touch to explain the project details and request a quote.